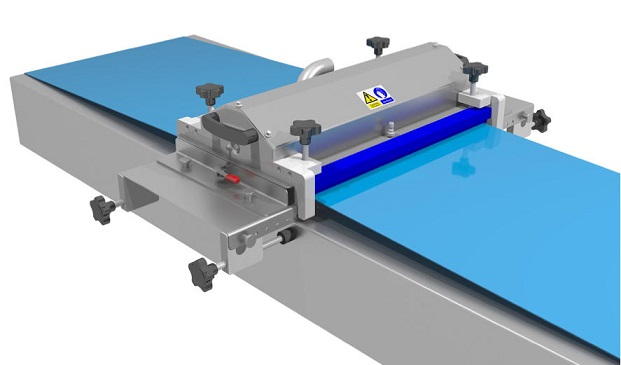

KHD BS2

Flexible cleaning system for flat belts

The KHD BS2 steam cleaning system uses a motorized brush to remove even stubborn dirt from the contact surface of the conveyor belt – without using chemicals.

The cleaning system is portable and setup is quick and easy. It can be used during production and without failure for conveyor belts of almost any size. The steam is evenly distributed across the entire width of the conveyor belt during the cleaning process to loosen the deposits and then disinfect the surface. The vacuum function then removes the deposits, leaving the conveyor belt dry and ready for use.

No interrupted production

Conveyor belt cleaning is carried out flexibly during the production time, there is no interruption of production. The burden on the sanitary, maintenance and repair personnel is also reduced.Eco-friendly and cost-efficient

The consumption of water and cleaning chemicals is greatly reduced. Compared to other conveyor belt cleaners a massive cost saving!Better hygiene and longer life

Fast, reliable disinfection and decontamination of conveyor belts – while production continues as normal. The conveyor belt cleaner leaves the flat belt clean, dry and ready for use.KHD18

The matching steam generator

Each of the steam generators manufactured according to KHD specifications has been designed for the process of conveyor belt cleaning. They have been specially optimized for use with our dry steam cleaners and contain special functions for this purpose. Furthermore, our generators have proven themselves in the entire field of steam cleaning and (dry) steam applications.